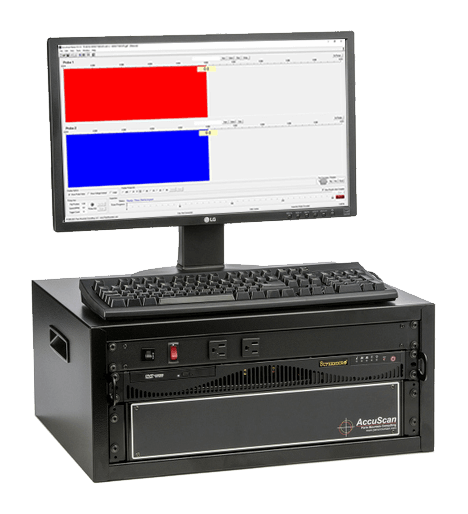

AccuScan m-Series

AccuScan m-Series

For measuring mechanical runout. Available in 2, 3 or 4 probe versions, featuring AccuScan software.

Turnkey circular geometry inspection system, with 2, 3 or 4 probes for measuring measuring mechanical runout, shaft runout, rotor runout.

Inspection system and computer are mounted in 16-gauge steel industrial tabletop enclosure suitable for a shop floor environment. Includes widescreen LCD monitor, keyboard and mouse. Fully configured, calibrated and ready to use.

Options and accessories are available for a variety of different inspection scenarios: