Measurement and Assembly Systems

Build it Once, Build it Right™

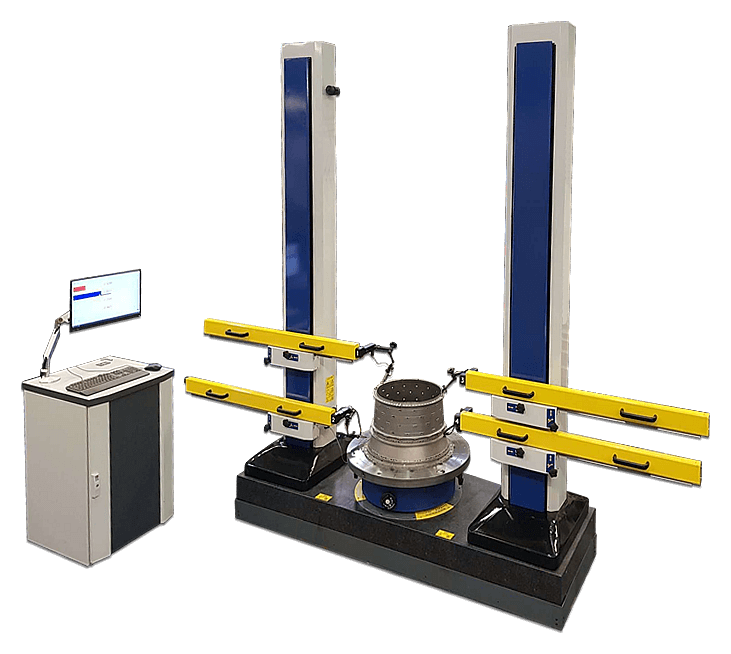

Aircraft Engine Measurement and Assembly

Complete solutions for

- OEM and MRO Aircraft Engine Assembly

- Industrial Compressor and Turbine Rotor Assembly

- Rotor Stacking

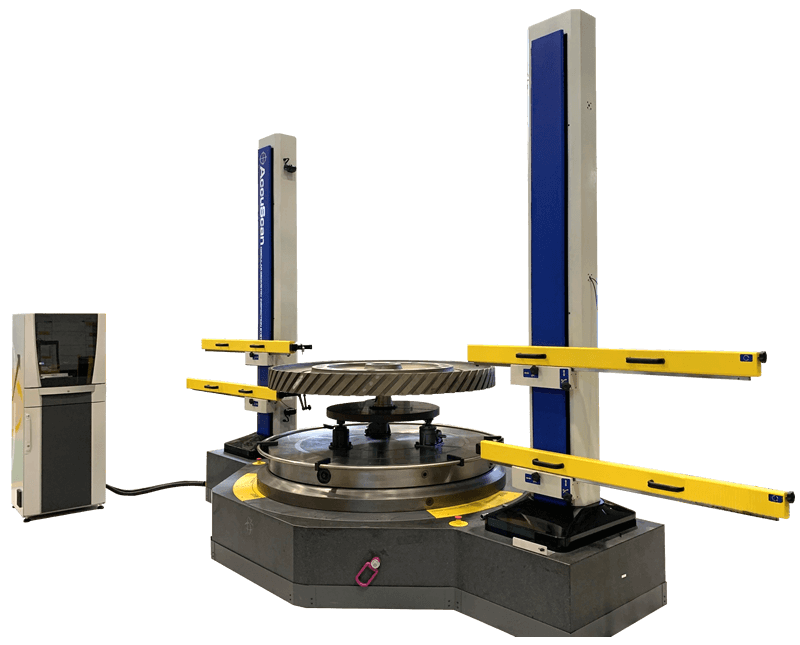

Measurement and assembly system features:

- An AccuScan m-RT Series inspection system

- Measurement resolution as low as 50 nm (2 μin)

- A motorized ultra high-precision air bearing rotary axis

- XY Centering and Leveling

- IntelliStack™ rotor stacking/assembly software, with predictive modeling of runout and unbalance

- Cylindrical measurement volume up to ∅3,600 mm x 6000 mm

- Load capacities as high as 35,000 kg (77,000 lb)

Industrial Turbine Measurement and Assembly