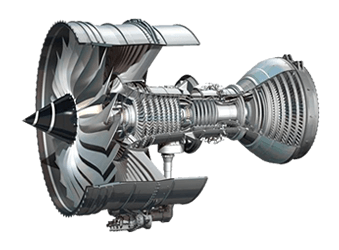

Precision Inspection and Assembly Solutions

for Aircraft Engines, Industrial Turbines and Compressors, Motors, Pumps, and other Rotating Machinery

Trusted by the world's leading rotating equipment manufacturers

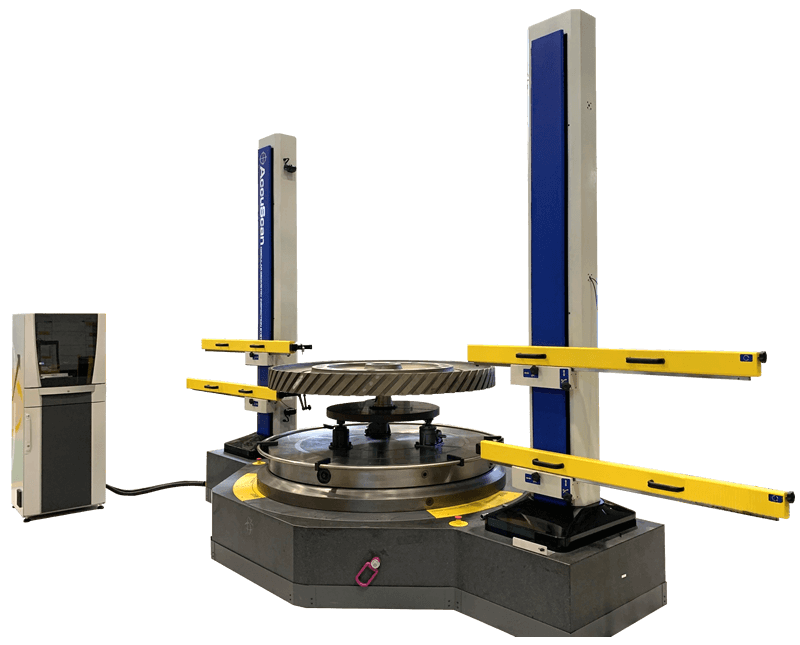

Runout Inspection

AccuScan Inspection Systems for Mechanical and Electrical Runout, with sub-micron precision.

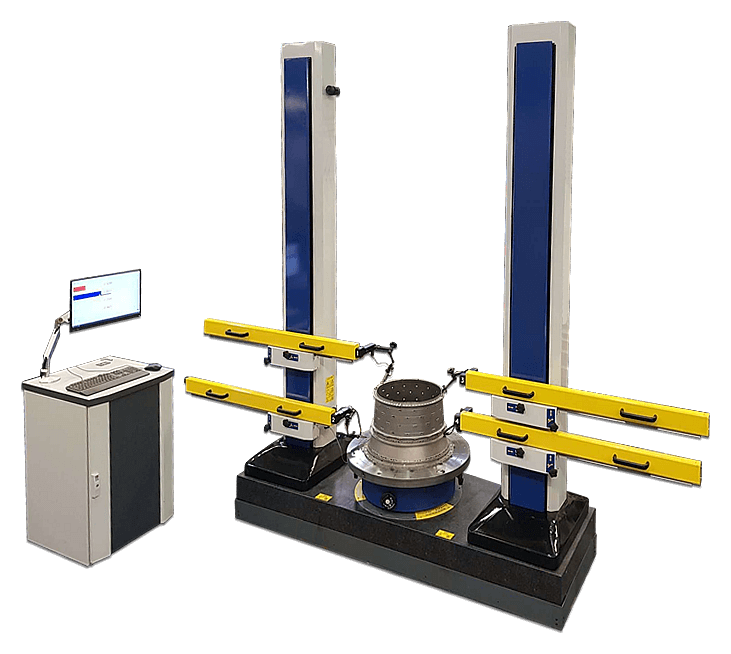

Measurement and Assembly

Measurement and assembly systems for aircraft engines and industrial turbines.

Reduce inspection time and gain new insight into part and rotor quality. With AccuScan, you can measure runout, roundness, flatness, and much more. Systems are available in various configurations, with or without rotary tables.

- Electrical Runout

- Mechanical Runout

- Permanent Inspection Records

- Out-of-Tolerance Highlighting

- English or Metric Units

- Inspection Templates

- Free Viewer

- Fully Responsive Results

- High-Density Data Acquisition

- Polar-Charting, Strip-Charting

- Revolution Repeatability Testing

- IntelliProbe™ Technology

"IntelliStack is the Holy Grail of rotor assembly"

Designed with Hands-On Expertise

Our inspection systems, assembly systems and software were designed by engineers with decades of real-world experience in the fields of circular geometry, high-precision rotating machinery, and rotor assembly.

We understand the challenges of measuring parts with tight tolerances and the need for measurement repeatability and accuracy. Contact us today. We're ready to answer your questions.